Manufacturing

Asian lessons for Africa

Manufacturing is underdeveloped in Africa, so its contribution to gross domestic product is dismally small. The continent’s share of the $ 12.3 trillion global market for manufactured goods was a mere 1.5 % in 2014, according to the London-based magazine The Economist. The continent’s industry needs to become more competitive to generate employment.

So far, Africa basically exports primary and semi-processed agricultural and mineral commodities. In the countries of origin, only little value is added. Raw materials made up 46.3 % of exports from sub-Saharan countries in 2014, but only 10.3 % of global exports, according to the World Bank.

At the same time, Africa has become a huge market for finished goods and services from other continents. Its foreign-exchange reserves are being drained because it is importing products that were made from African commodities abroad.

One option is to develop the textile and garment industry. Africa imports about 85 % of its new clothes from Asia – including traditional African dresses, by the way. The share is much too high given that African countries produce cotton, have masses of un- and underemployed people and are marked by considerable market demand.

When industrialisation set in anywhere historically, it normally started with textile and garment production. Bangladesh and Vietnam are recent examples. Both countries’ economies have been growing fast in recent decades, with manufacturing becoming ever more important. In both countries, moreover, poverty has been reduced considerably. African countries need that kind of success.

There are lessons to be learned. An overarching concern is the lack of infrastructure garment producers (and other manufacturing sectors) need: roads, electric power, water supply, ports, markets, financial services et cetera. These gaps drive up production costs.

Moreover, existing policies do not encourage investing in garment production in Africa. Because of smuggling, local markets are flooded with cheap imports that crowd out domestically-made items. As no taxes or duties are paid, government budgets suffer.

African economies must tap into every step along the textile value chain (spinning, weaving, dying, printing et cetera). There is scope for creating jobs for masses of unskilled people. So far, the region’s governments have largely failed to adopt policies that might drive this kind of development. They have not built the needed infrastructure, they have not passed the required regulations, and they have not adopted fiscal systems that would serve as incentives.

Labour costs are low in Africa, where textile employees currently earn $ 40 to $ 160 per month on average. Africa obviously has a competitive advantage in this respect. However, African companies tend to be very small, and only very few employ more than 200 persons. They can expand fast if the business and investment environment improves.

Africa’s manufacturing GDP grew by 3.9 % in 2014. Expanding public infrastructure would drive industrial development. In turn, rapid growth in the textiles sector would change Africa’s economic perspectives fast and drastically.

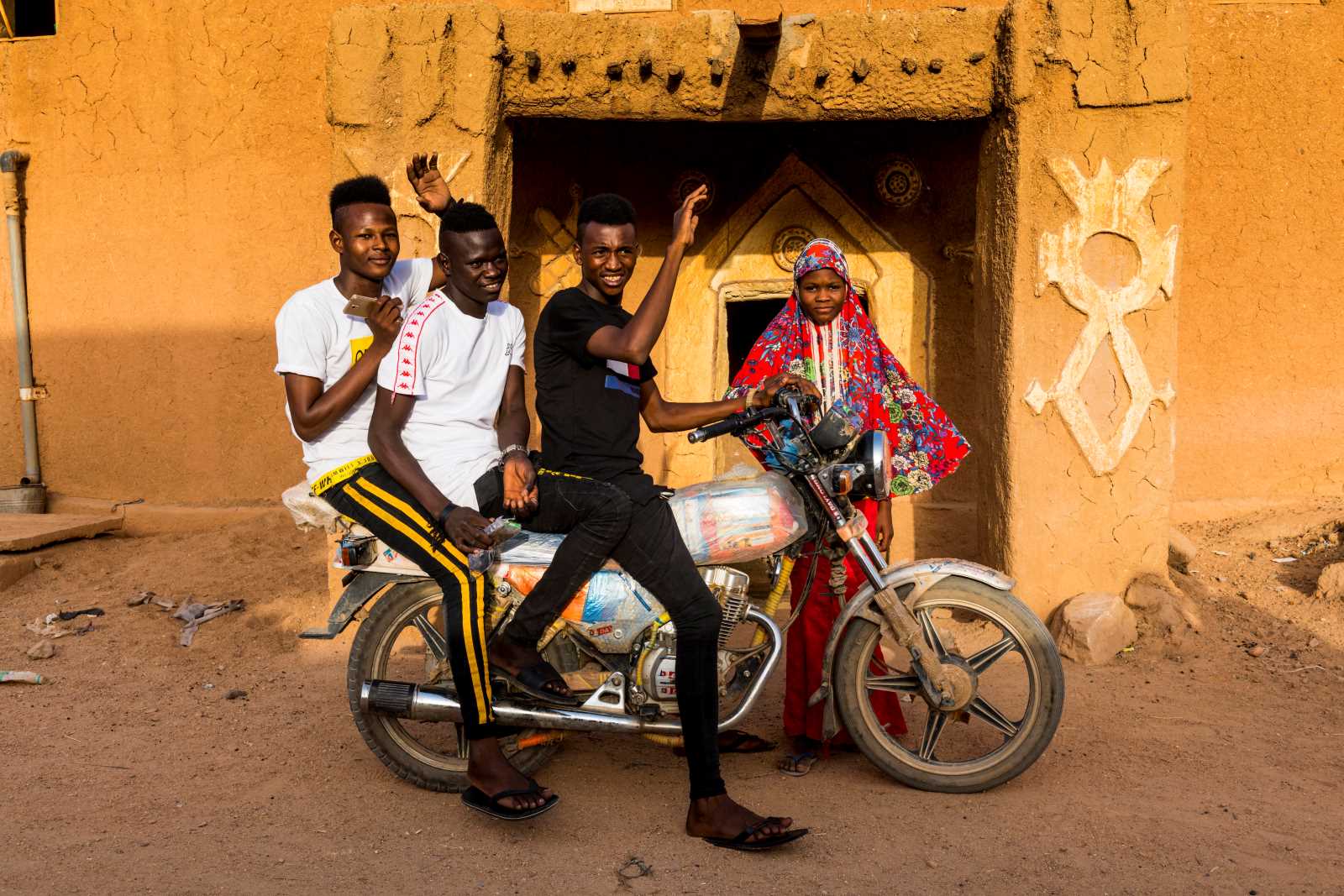

Africa is an ancient human habitat. It is ecologically diverse and blessed with a great variety of cultures. Its multitude of textile fabrics, prints and dresses – both traditional and modern – impresses consumers throughout the world. With an annual retail value of over $ 4 billion, embroidered and intricately patterned African clothes have garnered international attention. This is the launch pad from which development must take off.

African governments have committed to improving their peoples’ fate in the UN 2030 Agenda, which includes the Sustainable Development Goals, and in the Africa 2063 Agenda. Textile and garment production is a promising sector in this context. The sector can lift millions, if not hundreds of millions, from poverty.

Belay Begashaw is director general of the Sustainable Development Goals Center for Africa (SDGC/A) in Kigali, Rwanda.

bbegashaw@sdgcafrica.org